Short Lead Time for Ptfe Vacuum Tubing - Tube ptfe ID 2mm*OD 4mm for 3D printer | BESTEFLON – Besteflon

Short Lead Time for Ptfe Vacuum Tubing - Tube ptfe ID 2mm*OD 4mm for 3D printer | BESTEFLON – Besteflon Detail:

Product Details

| Brand Name: | BESTEFLON |

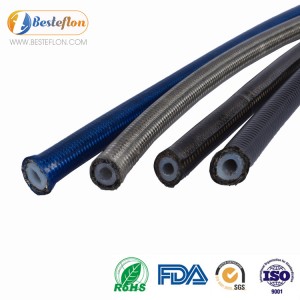

| Color: | milky white/translucent/black/blue/for your requiers |

| Specification: | ID 2mm*OD 4mm |

| Thickness: | 1mm |

| Material: | PTFE |

| Working Temperature Range: | -65℃-+260℃ |

| Application: | 3D Printer |

| Business Type: |

Manufacturer/Factory |

| Standard: | ISO9001 |

Smooth Bore Tubing Metric Range

| No. | Specification | Outer diameter | Inner diameter | Tube Wall Thickness | Working pressure | Burst pressure | |||||

| mm | (inch) | mm | (inch) | mm | (inch) | (psi) | (bar) | (psi) | (bar) | ||

| 1 | 1/8″*1/16″ | 3.17 | 0.125 | 1.58 | 0.062 | 0.8 | 0.031 | 218 | 15.0 | 725 | 50 |

| 2 | 3/16″*1/8″ | 4.76 | 0.187 | 3.17 | 0.125 | 0.8 | 0.031 | 174 | 12.0 | 638 | 40 |

| 3 | 1/4″*3/16″ | 6.35 | 0.250 | 4.76 | 0.187 | 0.8 | 0.031 | 131 | 9.0 | 464 | 32 |

| 4 | 5/16″*1/4″ | 7.93 | 0.312 | 6.35 | 0.250 | 0.8 | 0.031 | 102 | 7.0 | 363 | 25 |

| 5 | 3/8″*1/4″ | 9.52 | 0.357 | 6.35 | 0.250 | 1.5 | 0.059 | 174 | 12.0 | 638 | 44 |

| 6 | 3/8″*5/16″ | 9.52 | 0.357 | 7.93 | 0.312 | 0.8 | 0.031 | 87 | 6.0 | 319 | 22 |

| 7 | 1/2″*3/8″ | 12.7 | 0.500 | 9.6 | 0.378 | 1.5 | 0.059 | 131 | 9.0 | 464 | 32 |

| 8 | 5/8″*1/2″ | 15.87 | 0.625 | 12.7 | 0.500 | 1.5 | 0.059 | 102 | 7.0 | 363 | 25 |

| 9 | 3/4″*5/8″ | 19.05 | 0.750 | 15.87 | 0.625 | 1.5 | 0.059 | 87 | 6.0 | 319 | 22 |

* Meet SAE 100R14 standard.

* Customer-specific products may be discussed with us for detailed.

Smooth Bore Tubing Imperial Range

| No. | Specification | Outer diameter | Inner diameter | Tube Wall Thickness | Working pressure | Burst pressure | |||||

| mm | (inch) | mm | (inch) | mm | (inch) | (psi) | (bar) | (psi) | (bar) | ||

| 1 | 2*4 | 4 | 0157 | 2 | 0.079 | 1 | 0.039 | 148 | 10.2 | 444 | 30.6 |

| 2 | 3*5 | 5 | 0.197 | 3 | 0.118 | 1 | 0.039 | 148 | 10.2 | 444 | 30.6 |

| 3 | 4*6 | 6 | 0.236 | 4 | 0.157 | 1 | 0.039 | 148 | 10.2 | 444 | 30.6 |

| 4 | 5*7 | 7 | 0.276 | 5 | 0.197 | 1 | 0.039 | 148 | 10.2 | 444 | 30.6 |

| 5 | 6*8 | 8 | 0.315 | 6 | 0.236 | 1 | 0.039 | 148 | 10.2 | 444 | 30.6 |

| 6 | 8*10 | 10 | 0.394 | 8 | 0.315 | 1 | 0.039 | 148 | 10.2 | 444 | 30.6 |

| 7 | 10*12 | 12 | 0.472 | 10 | 0.394 | 1 | 0.039 | 118 | 8.16 | 370 | 25.5 |

| 8 | 12*14 | 14 | 0.551 | 12 | 0.472 | 1 | 0.039 | 118 | 8.16 | 370 | 25.5 |

| 9 | 14*16 | 16 | 0.630 | 14 | 0.551 | 1 | 0.039 | 118 | 8.16 | 370 | 25.5 |

| 10 | 16*18 | 18 | 0.709 | 16 | 0.630 | 1 | 0.039 | 118 | 8.16 | 370 | 25.5 |

| 11 | 20*24 | 24 | 0.945 | 20 | 0.787 | 2 | 0.079 | 74 | 5.1 | 296 | 20.4 |

| 12 | 50*54 | 54 | 2.126 | 50 | 1.969 | 2 | 0.079 | 74 | 5.1 | 296 | 20.4 |

Video

people also ask:

2.How to Remove Stuck Filament from PTFE Tube

4.Why Do Hot Ends Have A Ptfe Tube

Give Us A E-Mail

sales02@zx-ptfe.com

Product detail pictures:

Related Product Guide:

Our advantages are lessen charges,dynamic income team,specialized QC,sturdy factories,premium quality services for Short Lead Time for Ptfe Vacuum Tubing - Tube ptfe ID 2mm*OD 4mm for 3D printer | BESTEFLON – Besteflon , The product will supply to all over the world, such as: Indonesia , moldova , Greenland , We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

Question:What is the bending radius?

Answer:Different inner diameter has different bending radius. You can refer to our corresponding product specification table, which will have parameters. Or you can consult our business, we give you professional answers.

Question:What is the temperature resistance? I want to use in 200 ℃ working temperature environment, can I use it?

Answer:One of the characteristics of our products is high temperature resistance, the working temperature range is 65 ℃ ~ 260 ℃. Under normal use, the service life is as long as 50 years or even longer. It can be used at 200 ℃. It is generally recommended that you use imported materials, which will be more durable.

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!