Braided Hose Cover AN8 for Brake System | BESTEFLON

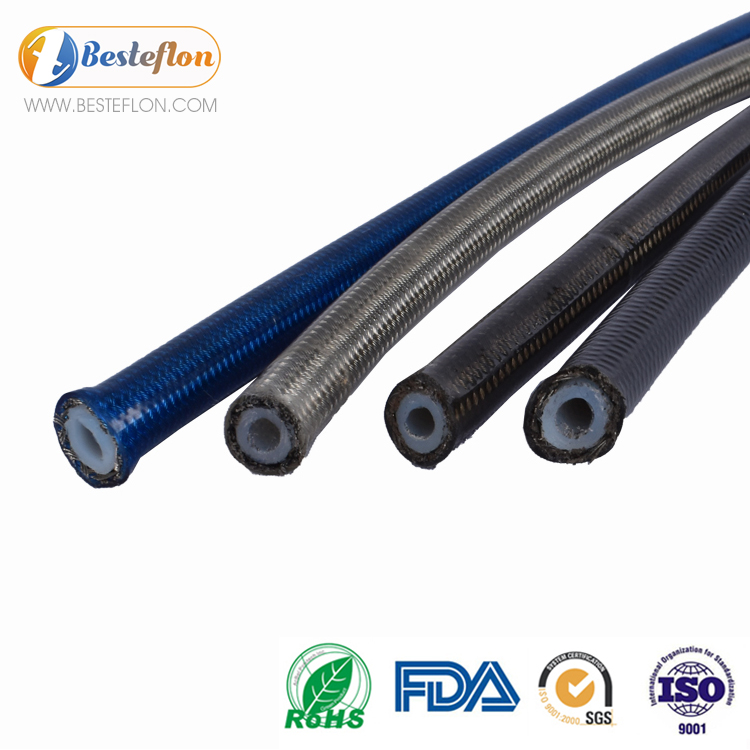

Braid hose cover refers to the braided reinforcement layer outside the inner tube. Different covers have different roles:

Stainless steel wire - Increasing hose working pressure, protect inner tube will not be destroyed by external forces;

PU/PVC - Good protect to stainless steel layer, suitable for automotive hose;

TPU - good protect to stainless steel layer

Silicone - heat insulation, abrasion;

Glass Fiber/ Dacron/ Cotton Yarn - heat insulation;

Motley Cotton Yarn - Thermal insulation an plays an important role in marking, available colors are black, white, blue, red, gray, etc;

Aramid Fiber - thermal insulation, increasing the working pressure;

Braided layer is very important for the PTFE smooth bore tubes and convoluted tubes, it can protect the inner tube from damage easily, but also can increase the working pressure and make the hose more flexible. Because of the special properties of PTFE, it is used in various industries. However, each industry has different requirements for these hoses performance. At this time, the braided cover with different functions can be better applied to each industry. If you need this, please check the above detailed explanation to choose your own way!

Advantage of PTFE braid hose cover

High temperature resistance

Insoluble in any solvents. It can withstand high temperature to 300℃ in a short time, and it can be used continuously between 240℃~260℃, and has remarkable thermal stability.

Corrosion resistance

Inert to most chemicals and solvents, resistant to strong acids and alkalis, water and various organic solvents, and can protect parts from any kind of chemical corrosion.

High pressure resistant

The working pressure after braided stainless steel wire is 500-4,700 psi or more. Widely used in hydraulic industry.

Light weight and flexible

It can greatly reduce the working intensity of the operator, easier to install.

Coated/Cover ptfe hose

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXGM112-04 | 3/16" | 4.8 | 0.358 | 9.1 | 0.033 | 0.85 | 2936 | 203 | 11745 | 810 | 2.953 | 75 | -3 | ZXTF0-03 |

| ZXGM112-05 | 1/4" | 6.4 | 0.409 | 10.4 | 0.033 | 0.85 | 2646 | 183 | 10585 | 730 | 3.189 | 81 | -4 | ZXTF0-04 |

| ZXGM112-06 | 5/16" | 8.0 | 0.512 | 13.0 | 0.033 | 0.85 | 2429 | 168 | 9715 | 670 | 3.622 | 92 | -5 | ZXTF0-05 |

| ZXGM112-08 | 3/8" | 10.0 | 0.591 | 15.0 | 0.033 | 0.85 | 1958 | 135 | 7830 | 540 | 4.331 | 110 | -6 | ZXTF0-06 |

| ZXGM112-10 | 1/2" | 13.0 | 0.701 | 17.8 | 0.039 | 1.00 | 2272 | 113 | 6818 | 450 | 7.165 | 182 | -8 | ZXTF0-08 |

| ZXGM112-12 | 5/8" | 16.0 | 0.854 | 21.7 | 0.039 | 1.00 | 1233 | 85 | 4930 | 340 | 8.307 | 211 | -10 | ZXTF0-10 |

| ZXGM112-14 | 3/4" | 19.0 | 0.969 | 24.6 | 0.039 | 1.00 | 1015 | 73 | 4205 | 290 | 338 | -12 | ZXTF0-12 | |

| ZXGM112-16 | 7/8" | 22.2 | 1.091 | 27.7 | 0.039 | 1.00 | 870 | 60 | 3480 | 240 | 421 | -14 | ZXTF0-14 | |

| ZXGM112-18 | 1" | 25.0 | 1.220 | 31.0 | 0.039 | 1.50 | 798 | 55 | 3190 | 220 | 539 | -16 | ZXTF0-16 | |

Learn more about BESTEFLON products

Video

Send Us A E-Mail

sales02@zx-ptfe.com

Question 1:What is the delivery date of my order?

A: It usually takes 5-40 days, which usually depends on the quantity of your order and our storage. For more information, please feel free to contact us and we will reply you within 24 hours.

Question 2: How to place an order?

1. If you are interested in our products, please tell us which model and quantity you need.

2. We will quote for you as required.

3. After confirmation, the invoice will be sent to you.

4. After receiving your deposit, we will produce as soon as possible.

5. Delivery after production.

Question 3: after-sale service.

A:Track the status again and again until the product arrives, and try to solve any problems you mentioned.

All our wire braiding is done by advanced braiding machines. The braiding process is shown below:

How to cut braided hose cover?

We use a cutting machine with grinding wheel.

The feature of this cutting machine is that the cutting surface after cutting is neat and without wear.

When cutting, mark the position to be cut on the hose, and then put the hose on the fixed operating table, so that the hoses can be quickly cut off, simple operation.

What Is Ptfe Hose Use For

The following introduction is the usage for PTFE hose in various industries:

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available