ptfe fuel hose ID 8MM*OD 12 | BESTEFLON

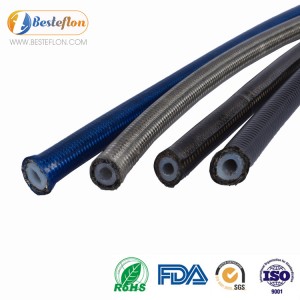

PTFE Fuel Hose is compatible for E85 gasoline, Ethanol and Nitromethane. The hard stainless steel outer braided provides impact resistance and abrasion resistance, and protects the PTFE inner tubing.

In addition, due to the fuel is a flammable and explosive liquid, our PTFE fuel hose has been specially carbonized, which plays a huge role in the discharge of static electricity and avoids unnecessary losses.

The PTFE fuel hose has a low coefficient of friction, allowing higher flow rates and easier flushing, while also helping to eliminate process contamination residues. This material has flexibility, chemical resistance, non-flammability and heat resistance.

For most chemicals and solvents, it also has high dielectric strength and inertness. It is not only suitable for the automotive industry, but also widely used in industry, chemical processing, general laboratories, automobiles, insulation and catering services.

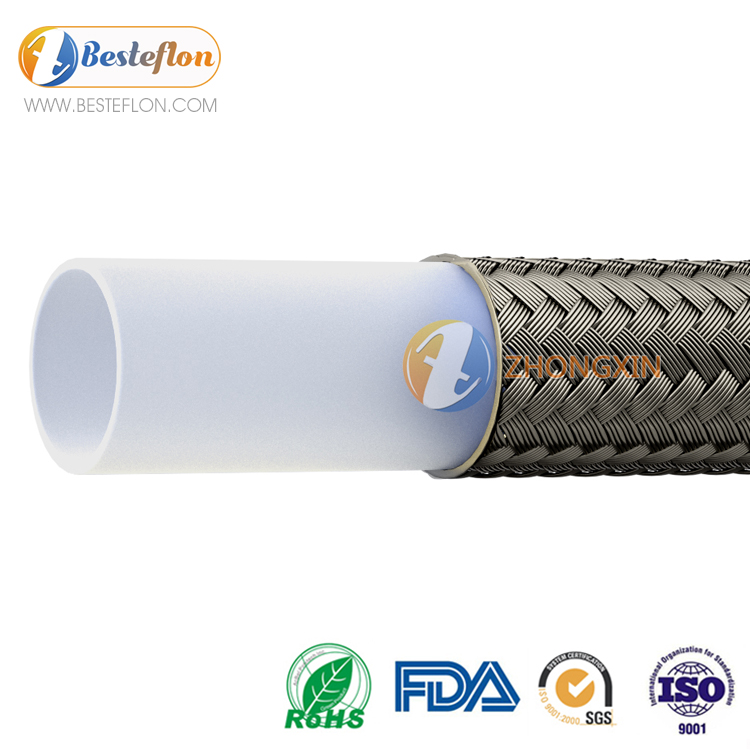

PTFE hose for fuel provides ultimate lubrication, high temperature use, chemical resistance, biocompatibility and precision extrusion tolerances. Since the inner diameter is clean and smooth, the PTFE hose allows limited free flow.

PTFE fuel hoses have very low permeability to gases and liquids. It is almost completely free from chemical attack, and can be reused in ethylene oxide and autoclaves. Fluoropolymer hose is considered to have high flexibility, but PTFE tubing has the best flexibility.

PTFE fuel hose is currently the thinnest and lightest fuel hose. It combines high elastic grade 304 stainless steel braid with internal smooth PTFE tube to increase flow. The complex external structure provides incredible flexibility. The internal PTFE tube is suitable for use with any fuel and can withstand temperatures up to 260 degrees Celsius. Besteflon’s stainless steel braided PTFE hose can be used to soak hose in fuel applications.

Our product specifications are complete, ranging from 1/8 to 2". And all the raw materials we use are high-quality; such as DuPont, 3M, Daikin, etc., and top domestic raw materials are also available.

BESTEFLON PTFE Hose has a low friction coefficient, allowing for higher flow rates and easier flushing, while also helping to eliminate residue from process contamination. This material is flexible, resistant to chemical corrosion, non-flammable, and heat resistant. It also has high dielectric strength and inertia for most chemicals and solvents. It is suitable for industrial, chemical processing, general laboratory, automotive, insulation, and food service applications. Related Searches: PTFE Smooth Bore Hose, Stainless Braided PTFE Brake Hose

Polytetrafluoroethylene (PTFE) tube for the industrial wall is widely used because of its excellent heat resistance, chemical corrosion resistance, and insulation performance. Since the inside diameter is clean and smooth, the PTFE tube allows limited free flow. The permeability of PTFE pipe to gas and liquid is very low. Polytetrafluoroethylene is almost completely free from chemical attack, but under special conditions, it will be affected by alkali metals and halogens. Polytetrafluoroethylene pipe is heat-resistant to 500 degrees Fahrenheit and is reusable for ethylene oxide and autoclave. Fluoropolymer tubes are considered to be highly flexible, but PTFE tubes have the best flexible life.

Smooth Bore Hose Range

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXGM111-03 | 1/8" | 3.5 | 0.220 | 5.6 | 0.039 | 1.00 | 3582 | 247 | 14326 | 988 | 2.008 | 51 | -2 | ZXTF0-02 |

| ZXGM111-04 | 3/16" | 4.8 | 0.315 | 8.0 | 0.033 | 0.85 | 2936 | 203 | 11745 | 810 | 2.953 | 75 | -3 | ZXTF0-03 |

| ZXGM111-05 | 1/4" | 6.4 | 0.362 | 9.2 | 0.033 | 0.85 | 2646 | 183 | 10585 | 730 | 3.189 | 81 | -4 | ZXTF0-04 |

| ZXGM111-06 | 5/16" | 8.0 | 0.433 | 11.0 | 0.033 | 0.85 | 2429 | 168 | 9715 | 670 | 3.622 | 92 | -5 | ZXTF0-05 |

| ZXGM111-07 | 3/8" | 9.5 | 0.512 | 13.0 | 0.033 | 0.85 | 1958 | 135 | 7830 | 540 | 4.331 | 110 | -6 | ZXTF0-06 |

| ZXGM111-08 | 13/32" | 10.3 | 0.531 | 13.5 | 0.033 | 0.85 | 1894 | 128 | 7395 | 510 | 5.157 | 131 | -7 | ZXTF0-06 |

| ZXGM111-10 | 1/2" | 12.7 | 0.630 | 16.0 | 0.039 | 1.00 | 2272 | 113 | 6818 | 450 | 7.165 | 182 | -8 | ZXTF0-08 |

| ZXGM111-12 | 5/8" | 16.0 | 0.756 | 19.2 | 0.039 | 1.00 | 1233 | 85 | 4930 | 340 | 8.307 | 211 | -10 | ZXTF0-10 |

| ZXGM111-14 | 3/4" | 19.0 | 0.902 | 22.9 | 0.039 | 1.00 | 1051 | 73 | 4205 | 290 | 13.307 | 338 | -12 | ZXTF0-12 |

| ZXGM111-16 | 7/8" | 22.2 | 1.031 | 26.2 | 0.039 | 1.00 | 870 | 60 | 3480 | 240 | 16.575 | 421 | -14 | ZXTF0-14 |

| ZXGM111-18 | 1" | 25.0 | 1.161 | 29.5 | 0.059 | 1.50 | 798 | 55 | 3190 | 220 | 21.220 | 539 | -16 | ZXTF0-16 |

| ZXGM111-20 | 1-1/8" | 28.0 | 1.299 | 33.0 | 0.059 | 1.50 | 725 | 50 | 2900 | 200 | 23.622 | 600 | -18 | ZXTF0-18 |

| ZXGM111-22 | 1-1/4" | 32.0 | 1.496 | 38.0 | 0.079 | 2.00 | 653 | 45 | 2610 | 180 | 27.559 | 700 | -20 | ZXTF0-20 |

| ZXGM111-26 | 1-1/2" | 38.0 | 1.732 | 44.0 | 0.079 | 2.00 | 580 | 40 | 2320 | 160 | 31.496 | 800 | -24 | ZXTF0-24 |

| ZXGM111-32 | 2" | 50.0 | 2.224 | 56.5 | 0.079 | 2.00 | 435 | 30 | 1740 | 120 | 39.961 | 1015 | -32 | ZXTF0-32 |

* Meet SAE 100R14 standard.

* Customer-specific products may be discussed with us for detailed.

| Brand Name: |

BESTEFLON |

| Material: | PTFE |

| Specification: | 1/8'' to 1'' |

| Thickness: | 0.85/1/1.2/1.5MM |

| Inside hose color: | milky white/translucent |

| Temperature range: | -65℃--+260℃ |

| Wire braided: | 304/316 stainless steel wire braided |

| Appliecation: | Chemical/Machinery equipment//Compressed gas/Fuel and lubricant handling/Steam transfer/Hydraulic systems |

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXGM111-03 | 1/8" | 3.5 | 0.220 | 5.6 | 0.039 | 1.00 | 3582 | 247 | 14326 | 988 | 2.008 | 51 | -2 | ZXTF0-02 |

| ZXGM111-04 | 3/16" | 4.8 | 0.315 | 8.0 | 0.033 | 0.85 | 2936 | 203 | 11745 | 810 | 2.953 | 75 | -3 | ZXTF0-03 |

| ZXGM111-05 | 1/4" | 6.4 | 0.362 | 9.2 | 0.033 | 0.85 | 2646 | 183 | 10585 | 730 | 3.189 | 81 | -4 | ZXTF0-04 |

| ZXGM111-06 | 5/16" | 8.0 | 0.433 | 11.0 | 0.033 | 0.85 | 2429 | 168 | 9715 | 670 | 3.622 | 92 | -5 | ZXTF0-05 |

| ZXGM111-07 | 3/8" | 9.5 | 0.512 | 13.0 | 0.033 | 0.85 | 1958 | 135 | 7830 | 540 | 4.331 | 110 | -6 | ZXTF0-06 |

| ZXGM111-08 | 13/32" | 10.3 | 0.531 | 13.5 | 0.033 | 0.85 | 1894 | 128 | 7395 | 510 | 5.157 | 131 | -7 | ZXTF0-06 |

| ZXGM111-10 | 1/2" | 12.7 | 0.630 | 16.0 | 0.039 | 1.00 | 2272 | 113 | 6818 | 450 | 7.165 | 182 | -8 | ZXTF0-08 |

| ZXGM111-12 | 5/8" | 16.0 | 0.756 | 19.2 | 0.039 | 1.00 | 1233 | 85 | 4930 | 340 | 8.307 | 211 | -10 | ZXTF0-10 |

| ZXGM111-14 | 3/4" | 19.0 | 0.902 | 22.9 | 0.039 | 1.00 | 1051 | 73 | 4205 | 290 | 13.307 | 338 | -12 | ZXTF0-12 |

| ZXGM111-16 | 7/8" | 22.2 | 1.031 | 26.2 | 0.039 | 1.00 | 870 | 60 | 3480 | 240 | 16.575 | 421 | -14 | ZXTF0-14 |

| ZXGM111-18 | 1" | 25.0 | 1.161 | 29.5 | 0.059 | 1.50 | 798 | 55 | 3190 | 220 | 21.220 | 539 | -16 | ZXTF0-16 |

| ZXGM111-20 | 1-1/8" | 28.0 | 1.299 | 33.0 | 0.059 | 1.50 | 725 | 50 | 2900 | 200 | 23.622 | 600 | -18 | ZXTF0-18 |

| ZXGM111-22 | 1-1/4" | 32.0 | 1.496 | 38.0 | 0.079 | 2.00 | 653 | 45 | 2610 | 180 | 27.559 | 700 | -20 | ZXTF0-20 |

| ZXGM111-26 | 1-1/2" | 38.0 | 1.732 | 44.0 | 0.079 | 2.00 | 580 | 40 | 2320 | 160 | 31.496 | 800 | -24 | ZXTF0-24 |

| ZXGM111-32 | 2" | 50.0 | 2.224 | 56.5 | 0.079 | 2.00 | 435 | 30 | 1740 | 120 | 39.961 | 1015 | -32 | ZXTF0-32 |

* Meet SAE 100R14 standard.

* Customer-specific products may be discussed with us for detailed.

Advantage

PTFE inner tube has a series of excellent properties

1) Long term use of 200 ~ 260℃ high temperature, low temperature is still soft and resistant to - 100 ℃;

2) Resistant to aqua regia and all organic solvents;

3) The best weather/aging resistance of plastic;

4) High lubrication, minimum plastic friction coefficient (0.04);

5) Adhesives with minimum surface tension and solid materials without adhesion of any substance;

6) Non-toxic physical inertness;

7) Excellent electrical performance, it is an ideal choice for class C insulation materials.

Give Us A E-Mail

sales02@zx-ptfe.com

You may also like

People also ask

Question:What is the bending radius?

Answer:Different inner diameter has different bending radius. You can refer to our corresponding product specification table, which will have parameters. Or you can consult our business, we give you professional answers.

Question:What is the temperature resistance? I want to use in 200 ℃ working temperature environment, can I use it?

Answer:One of the characteristics of our products is high temperature resistance, the working temperature range is 65 ℃ ~ 260 ℃. Under normal use, the service life is as long as 50 years or even longer. It can be used at 200 ℃. It is generally recommended that you use imported materials, which will be more durable.

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available